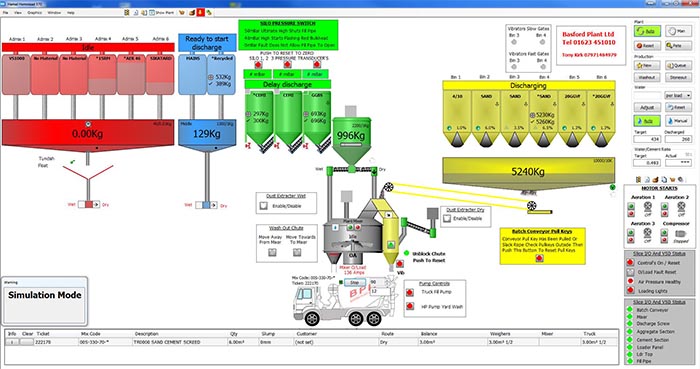

We have developed our own Concrete Batching Software which allows for the management of Ready Mix, Site Mixing, Precast and Screed/Mortar Plants.

Our Concrete Batching Plant Software delivers optimal plant performance with a very easy to use interface, meaning a concrete plant can be managed using just a keyboard and a mouse.

All of the daily functions that a plant operator would need are at their fingertips on the main display and more in-depth settings are securely protected. Plant operators will become very confident in using the Concrete Batching Plant Software package after just a short period of tuition.

Our concrete plant software provides a scalable and cost effective solution by utilising off-the-shelf components which are easily obtainable.

The Concrete Batching Software package allows your operator to control and monitor the entire concrete plant using just a keyboard and a mouse – allowing them to understand the performance of the plant and to spend their time efficiently.

Some of the features of our Concrete Batching Software

- Consistent and accurate batching with a unique, intuitive graphical plant interface and detailed management reports

- Easy control with a point and click display that only requires keyboard and mouse

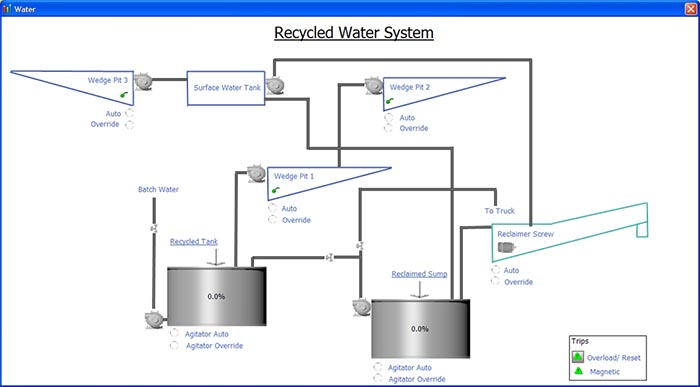

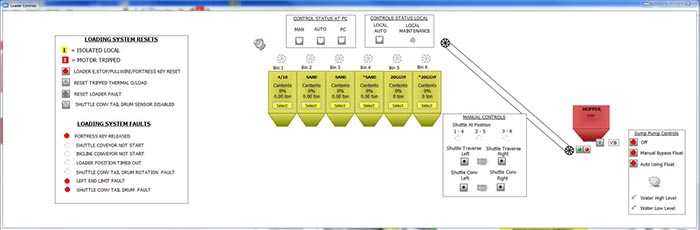

- Multiple screens can be used when control of loading and recycled systems are required

- Data link to shipping systems – allowing batch data to be received and actual batch results to be returned

- The system is easily scalable to any size/complexity of plant

- The system will allow for multiple secure graphical plant interfaces to be connected from any point with an internet/intranet connection – allowing for remote control, support, report viewing and will allow the technical parameters to be adjusted remotely

- Reports can be displayed before printing if required and can be exported to commonly used formats such as Word, Excel and PDF